Welcome to the last installment in this series. Today we’re taking a look at using Lean techniques as part of a process optimization initiative.

You’ve surely heard of Lean before and may have even dealt with Lean management up and close, so we’re not going to dive into its background. Instead, we’ll focus on a number of techniques and their benefits in the context explained above. This means we’re not going to touch on all existing Lean techniques, but rather exemplify some of them in an actual real-world example.

The way we’ll go about this is by following the DMAIC (Define, Measure, Analyze, Improve and Control) improvement process, a core tool in Lean-Six Sigma activities. DMAIC gives any improvement project much needed structure, and so in our case it will help bring clarity as we navigate the imagined scenario.

The purpose of this step is to shed light onto the issue(s) at hand, as well as the main goal, requirements and scope of the endeavor. The situation is as follows: a mainstream bank that offers a wide range of services notices that its customer service call center is voted the worst among its peers due to slow resolution times. The bank runs this area of its business in an industry-standard way so there is no initial immediate problem that stands out to them. In order to alleviate the situation, though, and improve the customer experience, management decides to investigate in more detail. This marks the start of our DMAIC process.

It is at this stage that a technique called Stakeholder analysis is used. With its help, the optimization team will be able to identify and elaborate on who the stakeholders are, how they influence the outcome. They also take note of stakeholders’ feedback. Now it comes as a surprise for the team spearheading the initiative that a majority of the employees in the Customer Support department find the hierarchy and existing processes unfit for purpose and are very eager to share their own vision for the department. Indeed, after carrying out the Stakeholder analysis, it turns out there is considerable strife among their ranks, which luckily can now be finally addressed. At the same time, the team creates a SIPOC table to maximize their understanding of the context at hand. With the process thus thoroughly defined from beginning to end, work can continue towards finding a solution.

During this stage, the process improvement team wants to learn all there is to know about the processes that make up the CS department’s activity. They use a Process mapping technique to create a schematic model of the process landscape, which highlights the high level of complexity of the software agents use to resolve tickets. It also makes visible things like bottlenecks and other related issues.

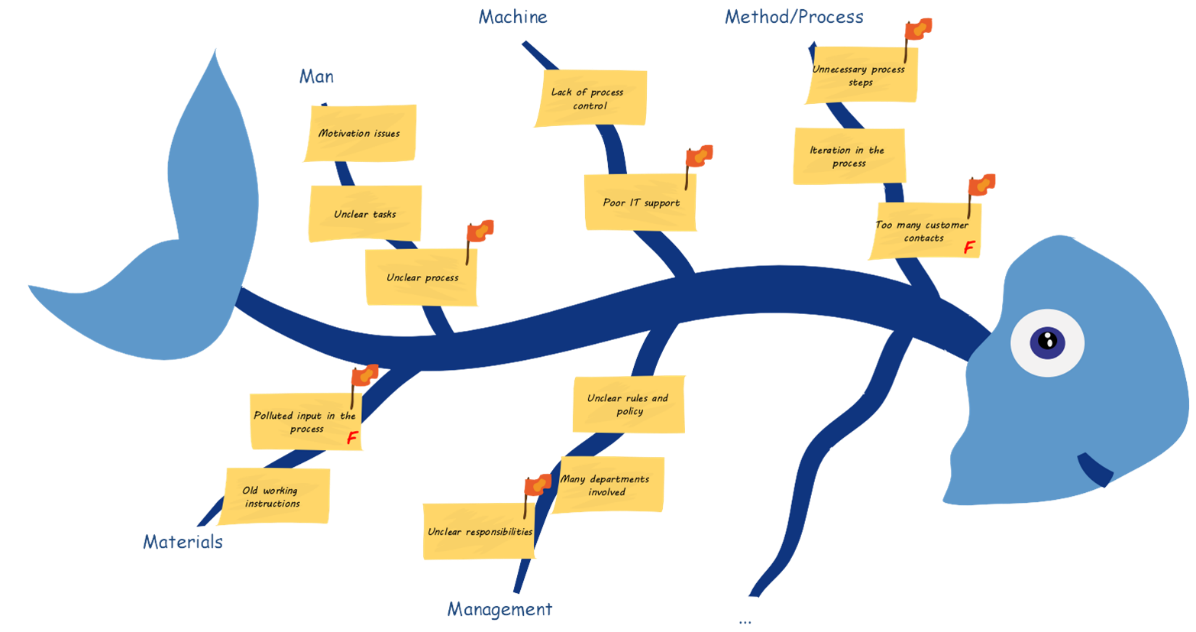

Then they employ a Fishbone diagram, which makes it obvious that the most widely encountered problem by staff is the range of issues they are being asked to tackle on a regular basis. According to the call center employees, the vast array of unpredictable situations created by the organization’s extensive products and services offering causes most of them to progress cases quite slowly. This is due to the fact that jumping between disparate scenarios, often involving services that are vastly

different, makes it impossible to build up an efficient cadence. Additionally, by using the Fishbone diagram during their workshops, the process improvement team learns that this is exacerbated by a lack of a repository where agents can share knowledge with one another or present interesting case studies and how they were resolved.

An example of a Fishbone diagram produced with BiZZdesign’s Horizzon platform

Apart from this workshop activity, the optimization endeavor also sees the use of a Checklist technique during actual workhours. This confirms previous accounts via actual direct observation and clarifies the incidence of negative points reported by staff. Finally, the team employs the Five times why technique during another batch of workshops to ensure they uncover any hidden underlying causes for the problems. This is a straightforward and effective way to get to the bottom of issues, and in the bank’s case it works beautifully, highlighting and solidifying candidates for improvement.

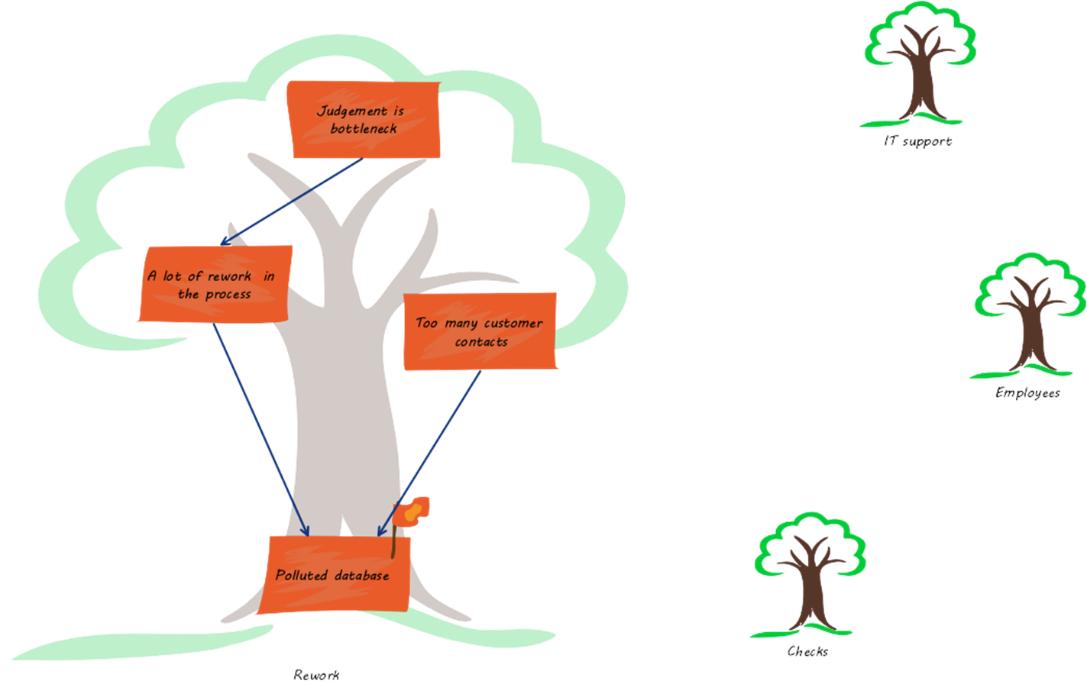

The third stage of the DMAIC process is analyzing the findings in order to come up with the most effective solution. Problems often have multiple causes. So, in order to properly focus their resources on the right obstacles, the bank in our scenario decides to utilize the Root cause technique to correctly identify the elements that are critical to the success of the project.

An example of a Root Cause analysis illustration produced with BiZZdesign’s Horizzon platform

This problem analysis tool allows them to identify three core problems within the department – the vastly different nature of the tickets that agents have to deal with on any given day; the poorly integrated and all-around inefficient software platform they’re using to investigate cases for customers; and thirdly, the inadequate organization of the department, whereby, human resources are poorly allocated and processes sluggish. With a good idea of what to address, the team gets to work.

The fourth stage of the DMAIC process is Improve. This is where the actual solutions are brought forth and changes get implemented. The main technique used at this point is Radical design. This simply means that everyone is asked during brainstorming sessions to try and envision a mode of work that is really efficient, both for the customer as well as the CS personnel, without – and this is key – paying any thought to real-world restrictions. So, what are the solutions they reach in the end?

Firstly, there is a division of labor between agents. Effectively they gain a specialization going forward, so that they no longer have to deal with products ranging from mortgages to insurance to the mobile app, payments issues etc. In the new system, everyone has a category (or categories) of tickets assigned to them so they only deal with the cases they specialize in. This brings in a certain level of excellence, which ultimately translates into them being (and sounding, if we’re really mindful of the customers) more knowledgeable as well as solving tickets faster! Not only that, but this way they also feel less stress at work and get higher satisfaction from performing a better job.

Secondly, a repository is created where agents have the ability and are actually actively encouraged to share their knowledge, with rewards awaiting those who rise to the challenge. In addition, a schedule is created for regularly organizing workshops during which staff present case studies of interesting problems, or workarounds for known bugs and so on. This reinforces a mentality of excellence and is a good means to spot candidates for promotions, too.

Thirdly, an incentives system is put in place to encourage the CS team to be at their best every day. In this initial iteration of the system, certain cash bonuses are offered to all the agents if the level of service is kept above a certain level, and the agent with the overall highest performance receives a bonus all for themselves.

We’ve reached the last stage in DMAIC – Control. This is a serious case of “last but not least”, since all the improvements in the world won’t make a difference, ultimately, unless they are sustained in the long term. The bank, therefore, formalizes the different specializations within CS with the help of the Human Relations department. This ensures the structure won’t disappear as soon as the present Global Head of CS leaves.

Another measure that they take is to create a quarterly meeting face-to-face between the Head of CS and the CEO, whereby updates and ongoing improvement programs are presented to the head of the company. This lends importance and legitimacy to the entire process improvement endeavor, making people it’s not a fad but an integral part of their mode of operation. In order to drive home this latter idea, a Lean technique called Day starts is implemented. This means at the start of the week, agents and managers get together to discuss ‘the good, the bad, and the ugly’ of the previous week and get everyone motivated for the week ahead (yes, they are called Day starts, but most companies really prefer a weekly approach).

And lastly, online questionnaires and email follow-up programs are created as part of their new KPI (Key Performance Indicators) approach. This is so as to provide constant feedback on the CS team’s performance and help with service level assessment.

To sum up, Lean techniques are a valuable tool that you can employ during process optimization initiatives. The established methodology and intense focus on increased efficiency add great value to the work of a business process improvement team, therefore boosting the likelihood of success. To learn more about Lean management please download our free Lean eBook or get in touch so we can tell you about our Lean services in more detail.